AS6171 Testing Services

AS6171- Test Methods Standard; General Requirements, Suspect/Counterfeit, Electrical, Electronic, and Electromechanical Parts

When sourcing electronic and electromechanical (EEE) parts, the legitimacy and authenticity of those parts are paramount. The AS6171 standard is the gold standard in testing and authenticating these components, especially those bought from the open market or gray market. Here’s a deeper look into the crucial realm of AS6171 testing and why counterfeit electronic components testing is so important.

Why AS6171 Testing is Essential

In the age of globalized manufacturing, the supply chain of electronic components has grown more complex than ever. The gray market presents an opportunity for counterfeit electronic parts to enter the system, potentially leading to fatal incidents.

What is the AS6171 Standard?

SAE AS6171, or simply AS6171, standardizes the inspection, electronic testing, and certification requirements for detecting Suspect/Counterfeit EEE parts. This ensures components are genuine and conform to the original part numbers as specified by the original component manufacturer (OCM).

The beauty of the AS6171 standard lies in its risk-based approach. Depending on the risk tolerance, one can opt for varying degrees of testing analysis.

Categories of Counterfeit Components Under AS6171

- Recycled: Components reclaimed from a system, then portrayed as new.

- Remarked: Legitimately made components, but with changed markings to misrepresent what the part is.

- Out-of-Specification/Defective: Non-conforming parts presented as conforming.

- Cloned: Unauthorized reproductions of the original component.

- Tampered: Typically seen in cloned chips, where sabotage or malfunction is introduced.

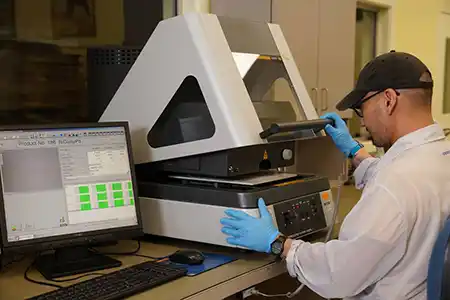

The Authentication Process by SMT Corp

Specializing in AS6171 authentication and certification, SMT Corp stands at the forefront of ensuring component integrity. For AS6171 certification, our EEE testing process involves:

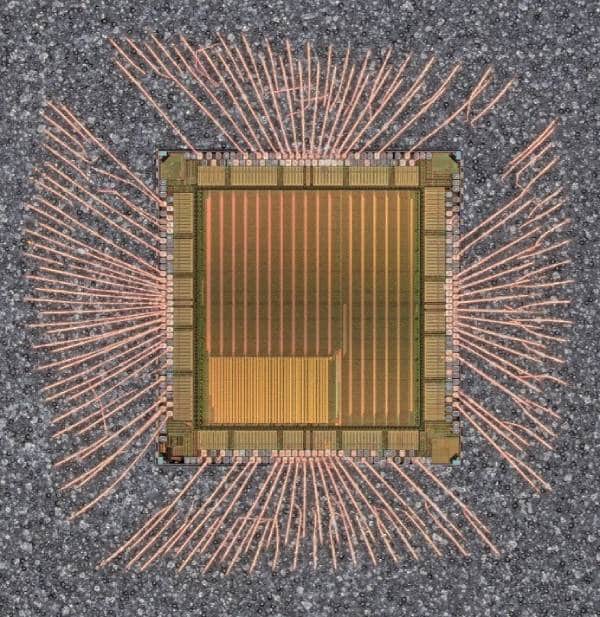

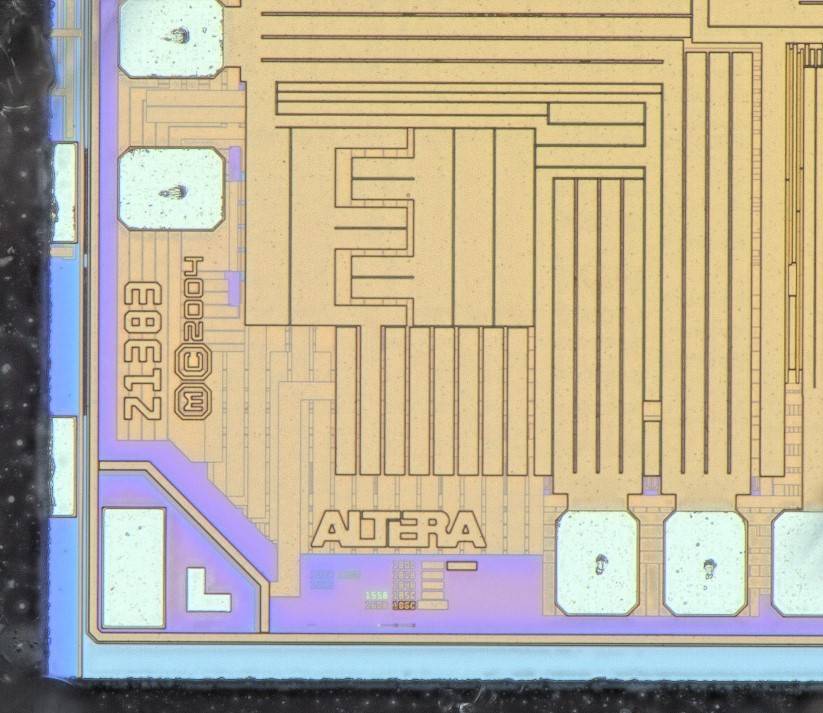

- External Visual Inspection: Utilizing electronic test equipment such as microscopes and xray inspection to visually examine electronic devices.

- Destructive Testing: Involves both chemical and mechanical methods.

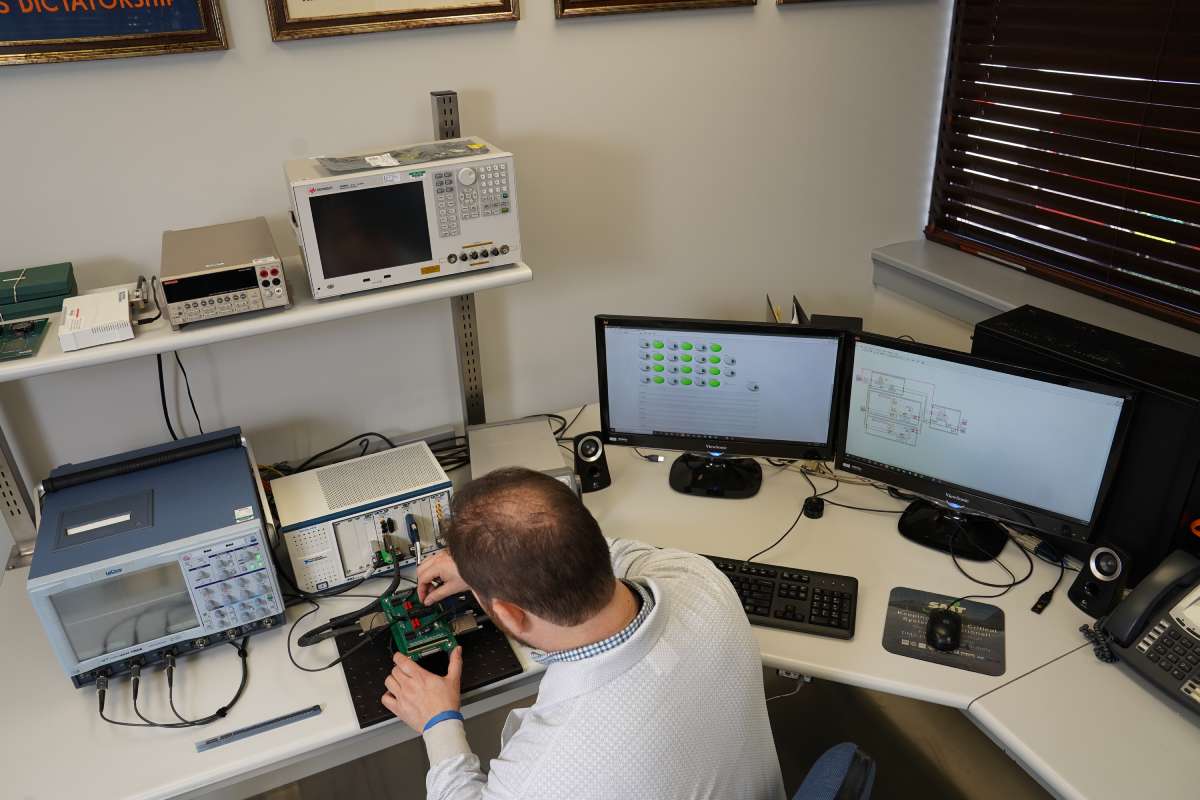

- Electrical Testing: By placing the component in a fixture, its performance is evaluated using tools like the digital multimeter and checking its power supply compatibility.

Why Choose SMT Corp for AS6171 Testing?

Besides being proficient in electromechanical testing and electronic testing, SMT Corp is unique in that they handle both the sourcing of authentic parts and the testing of third-party ones. Our reputation, particularly with government agencies like the Department of Defense, is unparalleled.

Our commitment to training and certification requirements ensures that our testing systems and electronic test equipment, such as the bench testing apparatus, are always up to the AS6171 test methods standard general requirements suspect counterfeit electrical electronic and electromechanical parts.

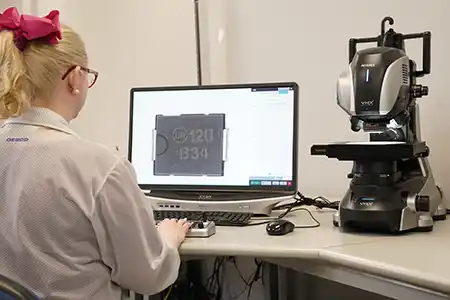

Keyence VHX-7000 Digital Microscope

AS6171/2 – External Visual Inspection

- Visual Inspection

- Packaging Configuration and Dimensions

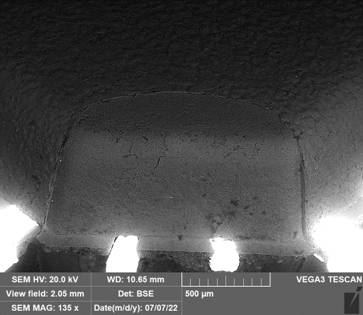

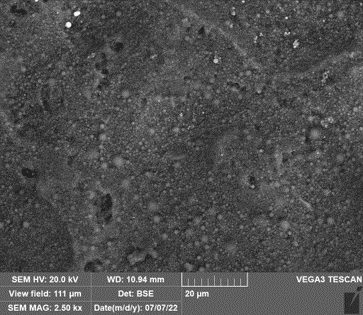

- Scanning Electron Microscopy Examination / Inspection

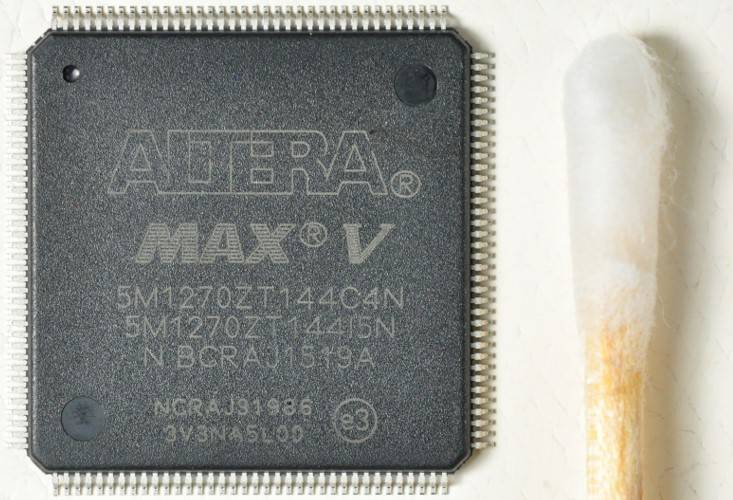

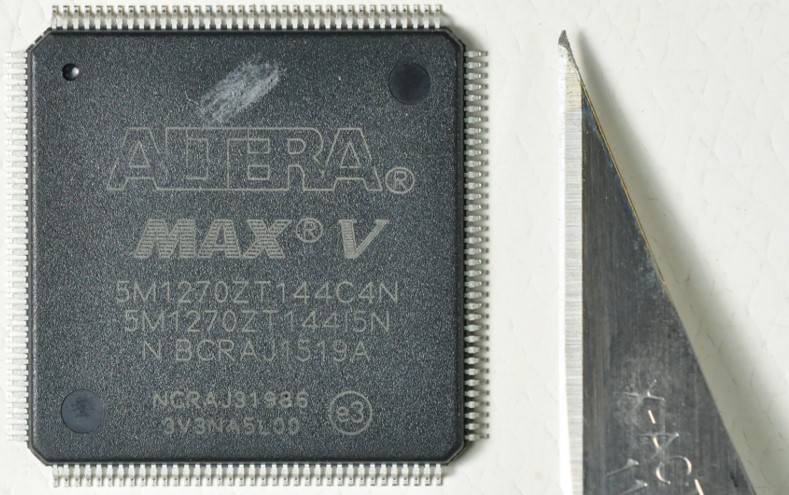

- Remarking and Resurfacing

- Resistance to Solvents / Scrape Test

- Dynasolve /1-Methyl 2- Pyrrolidinone

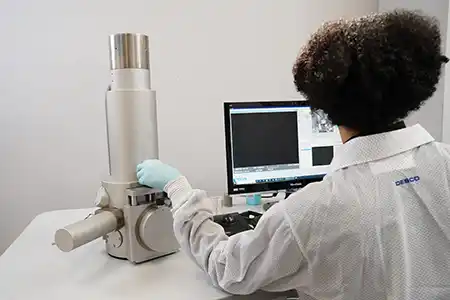

Tescan Vega3 Scanning Electron Microscope

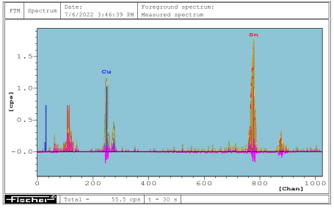

Fischer XDAL XRF

AS6171/3 – X-Ray Fluorescence

- X-Ray Fluorescence (XRF) Material Analysis

AS6171/4 – Delid/Decapsulation Physical Analysis

- Decapsulation and Die Verification

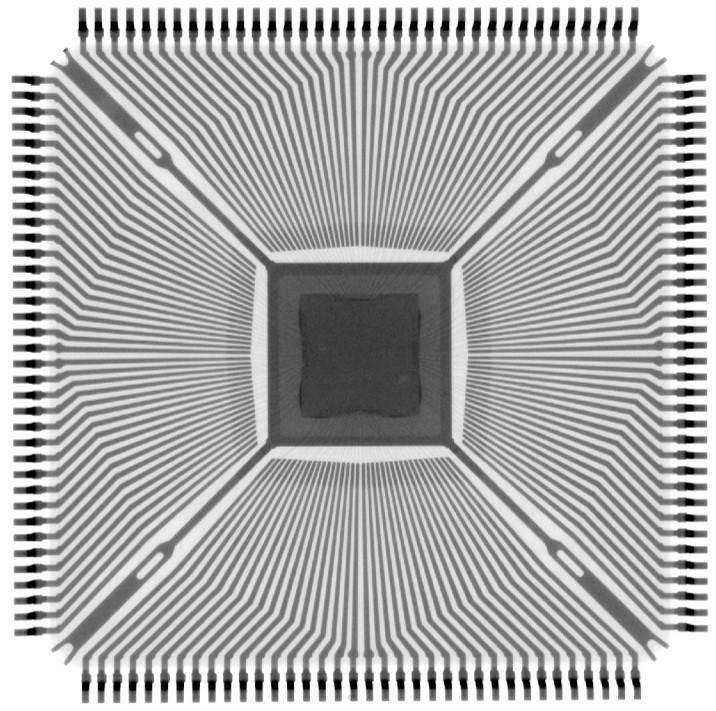

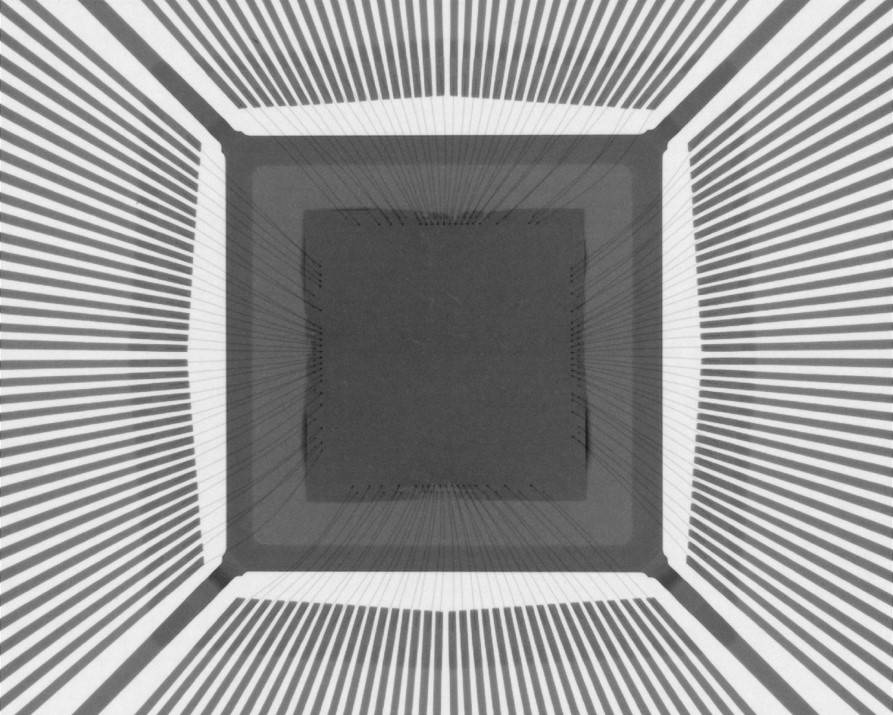

AS6171/5 – Radiological

- Radiographic Examination / Inspection

Nordson DAGE Quadra 5 with X-Plane

Nisene Jet-Etch Cu Protect Acid Decapsulator

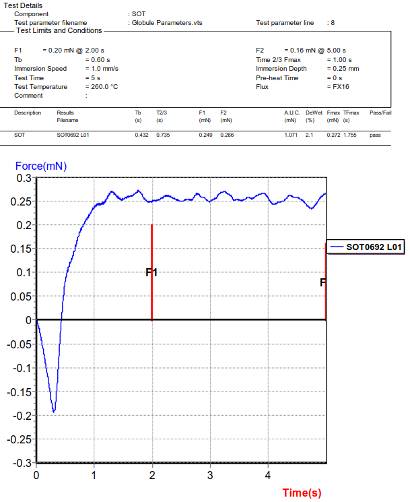

Force Wetting Solderability

- Compliance to IEC, IPC, MIL STD, EIA/JET, ISO, JEITA, and JNC standards

AS6171/7 – Electrical

- Capacitance Measurement (MIL-STD-202 Method 305)

- Contact Resistance (MIL-STD-202 Method 307)

- Forward Voltage Drop (MIL-STD-750 Method 4011)

- Reverse Current Leakage (MIL-STD-750 Method 4016)

- Regulator (Breakdown) Voltage (MIL-STD-750 Method 4022)

- Propagation Delay (MIL-STD-883 Method 3003)

- Power Supply Current (MIL-STD-883 Method 3005)

- High Level Output Voltage (MIL-STD-883 Method 3006)

- Low Level Output Voltage (MIL-STD-883 Method 307)

- Input Clamp Voltage (MIL-STD-883 Method 3022)

- Low Level Input Current (MIL-STD-883 Method 3009)

- High Level Input current (MIL-STD-883 Method 3010)

- Output Short Circuit Current (MIL-STD-883 Method 3011)

- Functional Testing (MIL-STD-883 Method 3014)

- Fine and Gross Leak Hermetic Seal (MIL-STD-750 Method 1071, MIL-STD-883 Method 1014)

- Temperature Cycling (MIL-STD-883 Method 1010.9, MIL-STD-750 Method 1051.9)

- Particle Impact Noise Detection (MIL-STD-750 Method 2052, MIL-STD-883 2020)

In an age where counterfeit electronic components can compromise both the integrity of electronic devices and, crucially, human lives, standards like AS6171 provide a beacon of assurance. Trust in a certified system and ensure your components stand up to the rigors of authenticity

AS6171/8 – RAMAN

-

AS6171/8 – RAMAN Spectroscopy

AS6171/9 – FTIR

-

AS6171/9 – Fourier Transform Infrared Spectroscopy (FTIR)