By Michael Schwarm, Chief Growth Officer, SMT Corp, July 25th, 2024

There is a strong rationale for why integrated sourcing and authentication of open market parts is the most effective approach when performed by a trusted and experienced independent distributor with in-house sourcing and accredited testing capabilities.

There are two primary schools of thought when it comes to the methodology for sourcing and authentication testing of electronic parts from the open market and other “untrusted” sources. While most OEMs (original equipment manufacturers) choose to contract with a single supplier with “in-house” sourcing and authentication testing capabilities, there are still some OEMs who source parts from one supplier and then have them tested by a 3rd party test house. Still other OEMs use a hybrid approach and don’t prefer one method versus the other. While both methods have the potential to be successful, there is a strong rationale for why integrated sourcing and authentication of open market parts is the most effective approach when performed by a trusted and experienced independent distributor with in-house accredited testing capabilities.

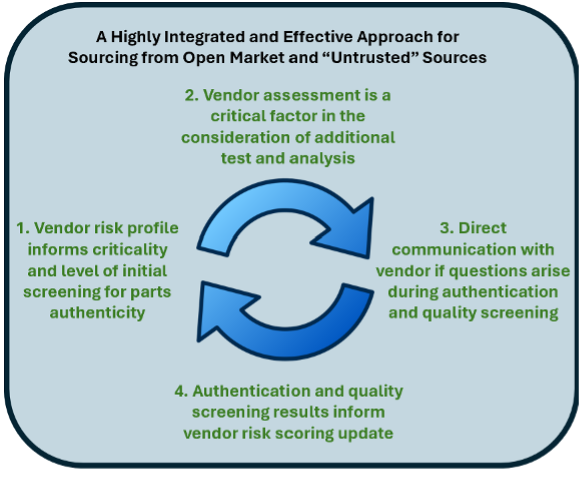

- As visualized in the figure below, the risk score for an open market parts vendor should be an input to the authentication plan, particularly if parts are being sourced from a vendor with a less than perfect risk score, or a vendor without a lot of history. Conversely, the results of prior authentication tests, even minor quality defects, should be considered when assessing risk for a parts vendor. This would be very difficult to accomplish with two or more companies performing sourcing and authentication. A closed loop system is best.

2. With a single provider of sourcing and authentication services, there is no “middleman” if questions arise during authentication testing. Information can flow between the parts vendor and the test lab clearly and effectively.

3. There is a single point of accountability for root cause determination in the case of a suspect counterfeit or ‘non-conforming’ part.

4. All related parts documentation, including sourcing and authentication information, is maintained by a single entity.

5. There is no financial risk to the OEM if there is a single company responsible for both sourcing and authentication, since there is no “finger pointing” or blame shifting.

6. Also, in the case of an integrated sourcing and authenticating approach through one provider, the overall lead time will be significantly less as there is no extra shipping or back and forth with two or more parties and no need for repetitive process steps such as incoming inspection. Furthermore, there is a single contract / purchase order for the OEM customer to manage.

7. There is a single point of accountability for ensuring compliance to all OEM customer and industry requirements and flow downs, including AS5553, AS6081, and AS6171. This reduces the number of suppliers the OEM customer must qualify; and ensures one point of accountability to be engaged with the end customer at the beginning of the contract / purchase order.

8. Lastly, the end customer may be able to take advantage of sourcing value to reduce or eliminate testing & authentication costs because value can be considered across all services being provided.

These points provide a compelling rationale for the effectiveness of integrated approach to sourcing and authentication via a single trusted provider. The argument against this approach is generally founded in mistrust of the “broker” market – that a single provider doing the sourcing and authentication is perversely incentivized to authenticate and deliver suspect or known counterfeit parts because they risk not being able to recover the cost of suspect counterfeit parts if that scenario arises; a “fox guarding the hen house” as it’s been referred to. While there is some merit to the argument given that there are many “less than reputable” independent distributors for open market parts, there are significant pitfalls and missed benefits by using separate providers for sourcing and authentication services.

- Contracting with two separate companies for sourcing & authentication creates significant risk as the 3rd party test house is not accountable for parts authentication and quality determination, only that they have run the minimum required by the test method. There are many times where 3rd party labs are insufficient, indecisive, and/or provide negative results as the test methods specified in AS6171 do not address research, diligence, root cause determination, and pressure testing.

- To further exacerbate the issue, the sourcing company usually doesn’t have the expertise to interpret the adequacy of 3rd party testing performed, and they are not incentivized to inquire further as many view the 3rd party test report as their “get out of jail free card”. Also, the sourcing company is left to make the determination on whether to accept or reject the parts based on the information provided by the test house, which is oftentimes incomplete and inconclusive. Note that this could be mitigated by the OEM taking responsibility for contracting the 3rd party test house, however that generally results in significant additional expense to the OEM and presumes the OEM has a sufficient level of expertise in counterfeit mitigation standards.

- Furthermore, 3rd party testing represents an additional expense to the sourcing company (or “broker”) if they are responsible for ensuring authenticity (which they should be), which oftentimes leads to them contracting with a “low cost” test house whose business model is to “crank out” as many test reports per day as possible, resulting in low quality work and minimal data and analysis in the reports.

- It is common industry practice for U.S., Canadian, British, and European companies to be responsible for the verification and quality of products they supply. If any company is going to be trusted to deliver products and services to the industries being served, particularly aerospace and defense – processes, reputation, and past performance need to be taken into consideration, as they are with all tiers in the supply chain.

- Under U.S. Code § 2320, it’s a federal offense in the U.S. to traffic in goods or services and knowingly use a counterfeit mark in connection with such goods or services. The penalty is up to $5M and 10 years in prison. Reputable companies based in the United States would typically not risk this.

In addition to the prior points, SMT Corp in particular, given its reputation as the industry leader in counterfeit electronics parts mitigation services, provides specific benefits:

- For companies specializing in counterfeit electronic parts mitigation, that have an integrated approach to sourcing and authentication like SMT Corp, a high percentage of potential counterfeit parts are screened out by visual inspection prior to authorizing vendor shipment to SMT Corp. Sourcing is an important part of the counterfeit mitigation process in addition to authentication testing.

- Long established companies with expertise in counterfeit electronic parts mitigation, like SMT Corp, have an established reputation to uphold as a trusted company for sourcing and authentication; they are singularly accountable for ensuring the authenticity and quality of parts sourced. And since there is no potential for finger pointing, SMT Corp has a lot more at stake than a company that provides only sourcing or only testing.

- SMT Corp provides customers with the most detailed test & authentication reports in the industry. Additionally, all data and images are archived by SMT Corp and available to our customers.

- SMT Corp performs blind testing, or pressure testing, for counterfeit parts detection to ensure the highest quality and integrity.

The purpose of this paper is to highlight the benefits of contracting with a well-established and well-respected supplier of integrated open market sourcing and in-house authentication testing services. A single, trusted supplier is the most efficient and effective methodology for mitigation of counterfeit electronic parts.

Epilogue

If you are still not convinced and are intent on using a 3rd party test house for your open market sourced parts, SMT Corp will support your needs as the most accredited, trusted, and experienced provider of authentication testing services. We can also source your open market parts and send them to a 3rd party for testing. That said, whenever SMT Corp sources from the open market we are responsible for ensuring the parts sourced are compliant with industry accepted standards, or specific customer flow-downs, so we are required to perform the appropriate level of inspection and testing in addition to the 3rd party. Additionally, being a U.S. based company, SMT Corp believes it is our obligation, and that we are the most qualified, to ensure we are not unknowingly passing through suspect counterfeit or poor-quality parts into the U.S., U.K, Canadian, and EU supply chain.

About SMT Corp

SMT Corp is an AS6081 / AS6171 accredited and industry recognized expert with full on-site sourcing, authentication, and electrical testing services to mitigate the risk of counterfeit, cloned, altered, or substandard electronic components from entering the Aerospace, Defense and critical infrastructure supply chain.