In April of 2023, Revision A of SAE Standard AS6081 for Counterfeit EEE (Electrical, Electronic, and Electromechanical) parts, which governs the Avoidance, Detection, Mitigation, and Disposition of EEE

Parts for Independent Distributors, was released. Amongst the changes in the standard was paragraph B.1.4, Test and Inspection Requirements. As a result of this change, the AS6081A standard now requires the supplier, in this case the independent distributor, to “comply with the inspection and test requirements of AS6171, to the extent specified by the [procuring] organization”. The historical version of AS6081, now superseded in its entirety by AS6081A, included test methods that were specific to AS6081. AS6081A no longer defines test methods unique to AS6081 and now defers to AS6171 (Test Methods Standard; General Requirements, Suspect/Counterfeit, Electrical, Electronic, and Electromechanical Parts) for test and inspection methods. What is not obvious from this change is what it means for “organizations” that are flowing down the prior version of AS6081 to their independent distributors. To put it bluntly, if the procuring organization is not flowing down AS6081A, then the organization is not compliant with the standard. Additionally, since the only test methods specified by AS6081A are the test methods in AS6171, any of the AS6171 test and inspection methods required by your organization need to be performed by one of the ten AS6171 accredited test labs in the world.

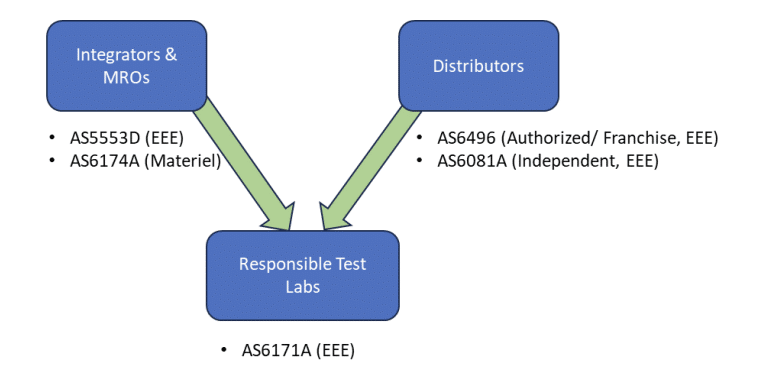

Another effect of AS6081A is to clarify the applicability of standards. The figure below shows the current relationship between standards focused on the mitigation of counterfeit EEE parts. The changes within AS6081A clarify the applicability of the standard to independent distributors, and positions AS6171 as THE standard for methods for testing and inspection of EEE parts to ensure authenticity and suitability.

In addition to referencing AS6171 tests methods, AS6081A no longer has a defined test regiment. This must be defined by the procuring organization and flowed down to the independent distributor based on an assessment of the organizations risk profile, which is typically a function of the part or part type, its usage, and the impact of potential failure.

The following table provides a comparison of the test methods specified in the prior, now obsolete, version of AS6081 with the roughly equivalent test methodology from AS6171. It’s important to note that AS6081A requires a Quality Management System (QMS) to be ISO9001 accredited whereas AS6171 requires ISO17025 and NAS-410 accreditation to apply for AS6171 accreditation. Therefore, the “bar” for a supplier to become accredited to perform AS6171 testing is much higher than it was for AS6081.

* Note that Table A is for comparison of AS6171 methods to the test methods defined in the obsolete version of AS6081

|

Test / Inspection Type |

Obsolete AS6081 Test Method |

AS6171 Test Method |

Differences between AS6171 & AS6081 test methods |

|

External Visual Inspection |

A1, A2 |

AS6171/2A |

AS6171 requires all images to be in lossless format and component weight measurements. |

|

Remarking and Resurfacing |

A3 |

AS6171/2A |

AS6171 requires aggressive acetone and Scrape testing. |

|

Radiological (X-Ray) Inspection |

A4 |

AS6171/5 |

AS6171 requires radiological images at both top (AS6081) and side profiles. |

|

Lead Finish Evaluation (XRF or EDS/EDX) |

A5 |

AS6171/3 |

No Differences |

|

Lead Material Composition |

N/A |

AS6171/3 |

AS6171 requires lead material composition. |

|

Delid/Decapsulation: Internal Inspection (Destructive) |

A6 |

AS6171/4 |

AS6171 requires bond wires to be preserved during decapsulation. AS6171 requires passive devices to be cross-sectioned. |

|

Electrical Testing |

C |

AS6171/7 |

AS6081 does not provide any specific definitions for electrical testing, only that it can be included. AS6171 specifies a variety of electrical tests including Static DC, Key Electrical Parameters, AC/Switching at +25C, AC/Switching at full operating temperature range, etc. |

Table A: Comparison of AS6081 and AS6171 Test & Inspection Methods

Prepared by SMT Corporation, 14 High Bridge Road, Sandy Hook, CT 06482 July 6th, 2023

Questions and Answers

Answer: AS6081A, which supersedes the prior version of AS6081, eliminates AS6081 specific test methods and now specifies the test methods as defined in AS6171. If your organization is flowing down inspection and test requirements as part of AS6081A, the only test and inspection methods reference…ill make it clear that performing testing in accordance with the obsolete version of AS6081 is no longer specified as part of the AS6081 standard and we will recommend that you make the seamless transition to our standard AS6171 test plan, at a minimum. SMT Corp. does reserve the right to perform whatever additional testing and inspection we believe may be required to ensure the parts are authentic if we are sourcing the parts.

Answer: If your contract is with the U.S. Department of Defense, the answer is most likely yes. DFARS requires Cost Accounting Standards (CAS) covered contractors to establish and maintain an acceptable counterfeit electronic part detection and avoidance system including inspection and testing of EEE parts. All contractors are responsible for inspection and testing when they obtain parts of questionable provenance; this is what is provided by AS6171.

Answer: AS6081A, released in April 2023, supersedes the prior version of AS6081. At the point where the updated standard was released, the old version of AS6081 became obsolete.

Answer: No. The AS6081A standard is the correct standard to flow down to independent distributors that are procuring EEE parts from the open market. The change means that the testing methods defined in your AS6081A flow-down are now provided by AS6171. It’s also important to note that you do not have to flow down test methods in AS6081A, for example, if you are contracting with a separate test house to perform your authentication.

Answer: Any effort made to mitigate counterfeit EEE parts is better than doing nothing. This includes measures such as visual inspection of parts, a robust vetting process for sourcing parts, radiological inspection, functional testing, and many more. While the term valid can imply many things, it is safe to state that performing testing and inspection based on the previous version of AS6081 is a good methodology for counterfeit mitigation but not as robust or up-to-date as the methods in AS6171. There are many enhancements in the AS6171 testing methods to address the increasing complexity of EEE counterfeit parts, and performing testing in accordance with the test methods in the prior version of AS6081 is no longer included in the AS6081A standard. If your organization requires alignment with the standard, which is there to ensure the test methods are reasonably aligned with your organization’s overall risk assessment, then your organization should have a plan that is based on the methods defined in AS6171. Additionally, AS6171 is increasingly being mandated by government and industry organizations so it is only a matter of time before most organizations will have to adopt these test methods.

Answer: SMT Corp. can work with your organization to develop a risk-based assessment and test plan based on the test methods in AS6171 – we do not charge customers for this service. SMT Corp. also offers a standard test plan based on AS6171 moderate risk level 2 (without electrical testing) that is the same price as what we charge for the previous AS6081 testing standard. This test plan covers the elements of the prior AS6081 test regiment and includes the additional steps as described in the prior table.

Answer: Yes, if specifically requested by our customer. However, if you have flowed down AS6081 as a standard to us we will make it clear that performing testing in accordance with the obsolete version of AS6081 is no longer specified as part of the AS6081 standard and we will recommend that you make the seamless transition to our standard AS6171 test plan, at a minimum. SMT Corp. does reserve the right to perform whatever additional testing and inspection we believe may be required to ensure the parts are authentic if we are sourcing the parts.

Answer: SMT Corp. can offer this immediately. Your next order can be switched to the test methods of AS6171. Our standard AS6171 test regiment also has no impact on your cost or lead time.

About SMT Corp

SMT Corp, located in Sandy Hook Connecticut, is an AS6081 / AS6171 accredited and industry recognized expert with full on-site sourcing, authentication, and electrical testing services to mitigate the risk of counterfeit, cloned, altered, or substandard products from entering the Aerospace and Defense industry critical supply chain.