Skip to content

Components Sourcing

- Counterfeit electronics mitigation begins with counterfeit avoidance

- SMT Corp. sources from our network of 200+ Approved Suppliers

- 1,400 Restricted Suppliers

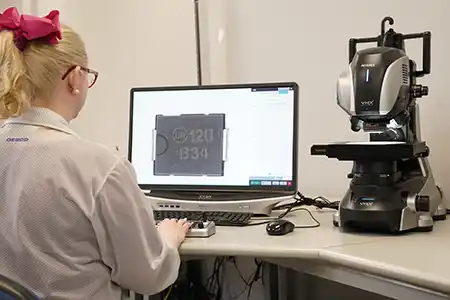

Enhanced Visual

- 100% Visual Inspection @ 2.5x – 125x+ magnification in accordance with AS6081/AS6171

- Detailed visual and dimensions performed on Keyence VHX-7000 Series Digital Microscopes

- High resolution photography of test samples

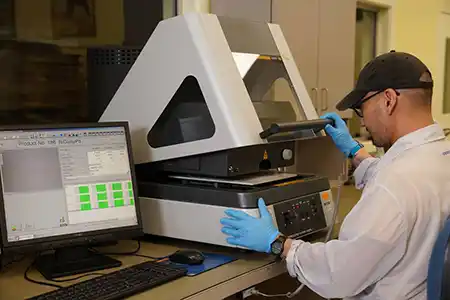

X-Ray Inspection

- 100% X-Ray inspection utilizing Nordson Dage Quadra 5 X-Ray Systems w/ micro CT 3D Imaging Capabilities

- Creative Electron Tru-View Reel to Reel X-Ray system for 100% Automated Inspection

- Each SMT Corp. electronics inspector is NAS-410 Level 1 Certified

XRF

- X-Ray Fluorescence material analysis of package terminals / leads and body

- Fischerscope XDAL X-Ray Fluorescence systems

- Hi-Rel, RoHS, and Lead-Free Analysis

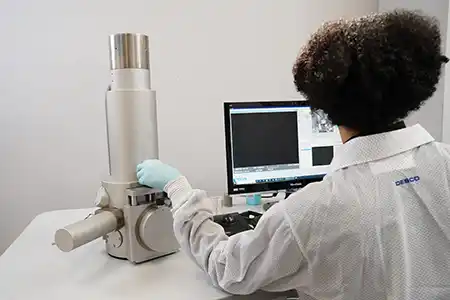

Scanning Electron Microscopy

- Tescan Vega3 Scanning Electron Microscopes with secondary and backscatter detectors

- Up to 500k magnification

- High resolution imaging for component package analysis

Resistance to Solvent and Heated Solvent

- Mineral Spirit / Alcohol marking permanency

- Acetone resistance to solvents

- MIL-STD-883 Resistance to Solvents

- Dynasolve 750 and N-Methyl-2-pyrrolidone heated solvent per AS6081 and AS6171

Solderability

- Gen3 MUST III Force Wetting Solderability per IEC 60068-2-69, J-STD-002, and MIL-STD-883 method 2022

- Quantitative and repeatable

- Testing of Leaded and Lead-Free devices

- Measurements down to 0.001mN

Decapsulation / Die Verification

- Acid etch decapsulation using Nisene JetEtch Pro CuProtect decapsulation systems

- >90% red fuming nitric acid and sulfuric acid for etching of plastic encapsulated (PEM) devices

- Die verification supported by SMT Corp.’s vast ‘gold sample’ die image library

RAMAN

- RAMAN Spectroscopy

- Qualitative surface analysis of component surface using an laser source per AS6171/8

- Surface comparison performed against SMT Corp.’s comprehensive RAMAN spectrum library

FTIR

- Fourier Transform Infrared Spectroscopy (FTIR)

- Qualitative surface analysis of component surface using an Infared light source per AS6171/9

- Surface comparison performed against SMT Corp.’s extensive FTIR spectrum library