By Michael Schwarm, Chief Growth Officer, and Mark Carpenter Jr., Software Developer, SMT Corp, September 25th, 2024

Introduction

SMT Corp’s ARGUS platform is an important tool for our engineers to protect the integrity of your electronic component supply chain in an increasingly automated and complex environment. Counterfeit components pose a significant financial, operational, and reputational risk. SMT Corp’s ARGUS platform offers two key benefits:

First, it improves customer support by significantly reducing lead times and ensuring faster delivery of results.

Second, it minimizes the time spent compiling part graphics, data and test reports, allowing our technicians and engineers to focus on the more important work of analyzing component test data and results.

This not only increases SMT Corps’ productivity, but also speeds up project turnaround times, leading to faster decision making and better outcomes for customers – further enhancing SMT Corps’ best in class counterfeit parts avoidance and detection capabilities.

From Data to Decisions: How ARGUS Accelerates SMT CORP’s Project Timelines

How does ARGUS help SMT Corp maintain high product quality standards, reduce lead times, and ultimately increase customer confidence and satisfaction – key factors for long-term protection of the electronic components supply chain?

The platform is designed to:

- Be flexible and efficient so that it can be set up either onsite or in the cloud, wherever is most convenient, and is easily accessible in the labs, where the testing takes place, so that the whole process runs smoothly and efficiently.

- Provide instant information on resource availability and progress, helping the testing team stay organized and make the best use of time.

- Allow inspection staff to focus on capturing important data instead of dealing with technical issues.

- Have user interfaces tailored to the specific roles and responsibilities for example:

- Test Technicians: use a task-based interface that simplifies their workflow, focusing on time tracking and scientific data collection. This design allows them to stay focused on their core responsibilities without unnecessary distractions.

- Senior Lab Technicians and Management: have access to a big-picture interface delivering a view of the entire testing process. They have the ability to assign work, view process maps, and manage data collection protocols, enabling them to make informed decisions about resource allocation and testing priorities.

- Support Staff: manage critical backend functions, including support equipment maintenance, customer requirement tracking, inventory management, and high-level order details. This ensures seamless coordination of all support functions across the lab.

- Provide flexible data collection covering:

- Versatile Data Handling: supports a wide range of data formats, from simple text to complex image arrays.

- Flexible Interfaces: for data collection and expanding data on the fly means that our testing processes can adapt quickly to new requirements. This agility accelerates project timelines.

- Consistency and Scalability: by refining requirement templates, tagged flowdowns, and Acceptable Quality Level (AQL) structures, to ensure that testing processes are consistent and repeatable.

- Enhanced Data Collection enables seamless integration with additional workflows for further analysis. This capability allows us to derive deeper insights from data, supporting better decision-making and driving continuous process improvement.

- Risk Mitigation: to ensure accurate and comprehensive data collection helps identify potential issues early in the testing process, reducing the risk of product failures, recalls, and legal liabilities.

- Deliver programmatic report generation using automated tools to generate reports based on predefined templates and data inputs, reducing the need for manual intervention and minimizing the risk of human error.

It’s important to note that even though the report assembly process is more automated, the analysis and review process remains human based. Research and analysis are regarded as SMT Corp’s core competencies. SMT Corp doesn’t just run tests as defined by industry standards, like AS6171 – we leverage our 25 years of knowledge and training to provide the best counterfeit component mitigation services in the world.

Flexible and Efficient: ensuring a future-proof platform

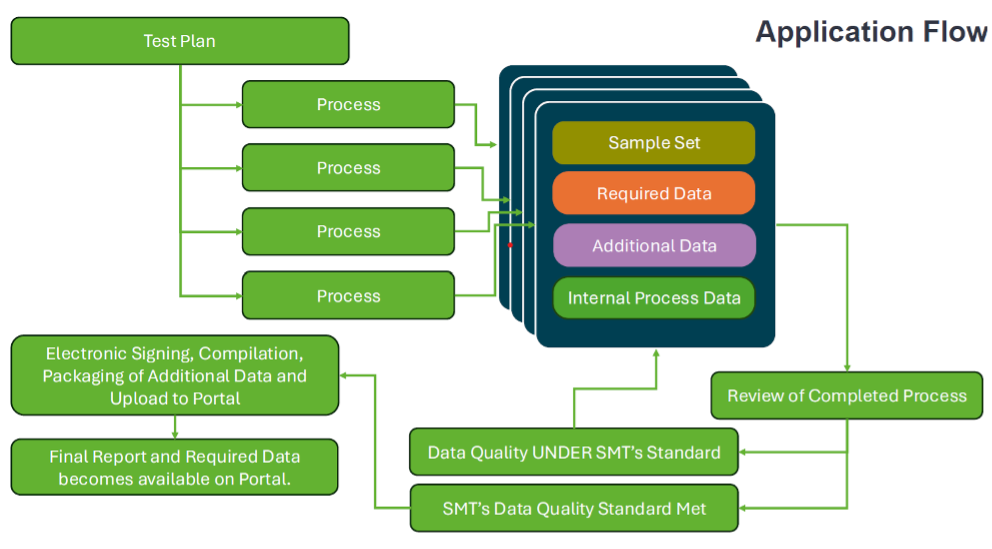

SMT Corp’s ARGUS platform, as visualized below, is engineered to be a future-proof platform, capable of adapting to evolving requirements and technologies. Its structured approach to data collection allows for continuous refinement of requirement templates, tagged flowdowns, and Acceptable Quality Level (AQL) structures. This ensures that our testing processes remain consistent, repeatable, and scalable, supporting long-term business growth and operational excellence.

Here’s how:

-

- Modular Architecture: ARGUS’s modular design allows for easy integration of new technologies and tools. This ensures that as new advancements emerge, they can be seamlessly incorporated into the platform without disrupting existing processes.

- Scalable Data Management: The platform’s structured approach to data collection and management supports scalability. This means it can handle increasing volumes of data and more complex data types as new technologies are adopted.

- Continuous Updates: SMT ARGUS is built to support continuous updates and improvements. This ensures that the platform remains up to date with the latest technological advancements and industry standards.

- Customizable Workflows: The platform allows for the customization of workflows to accommodate new testing methods and technologies. This flexibility ensures that ARGUS can adapt to changing requirements and maintain efficiency.

- Future-Proof Design: By incorporating a future-proof design, ARGUS can evolve alongside technological advancements, maintaining its relevance and effectiveness over time.

SMT Corp’s ARGUS: Pioneering the Future of Componet Authentication

In summary, SMT Corp ARGUS platform is a key pillar in the automation and digitalization of the critical analog flow within the AS6171 component authentication process. This innovation is essential to meet the ever-evolving needs of our customers and ensure shorter and more predictable test lead times. By utilizing ARGUS, we remain flexible and resilient in the fight against suspect and counterfeit components.

With ARGUS, we are not only keeping pace with the industry, but setting new standards for efficiency, accuracy, and customer satisfaction. With this platform, SMT Corp continues to deliver unparalleled quality and reliability, underscoring our commitment to excellence and supporting our customers with the highest level of quality and efficiency in the fight against counterfeit electronic parts.

How SMT ARGUS Supports Counterfeit Mitigation and AS6171 Standards

SMT’s ARGUS system ensures real-time vigilance, much like the all-seeing ARGUS Panoptes from mythology, by helping our engineers monitor the authenticity of electronic components. Its advanced data acquisition capabilities enable compliance with the stringent inspection and testing requirements of AS6171 standards. SMT ARGUS also ensures transparency and traceability by providing accurate, timely data on the authenticity of components, in the same way the media reports facts.